EWP Solutions

EWP Solutions

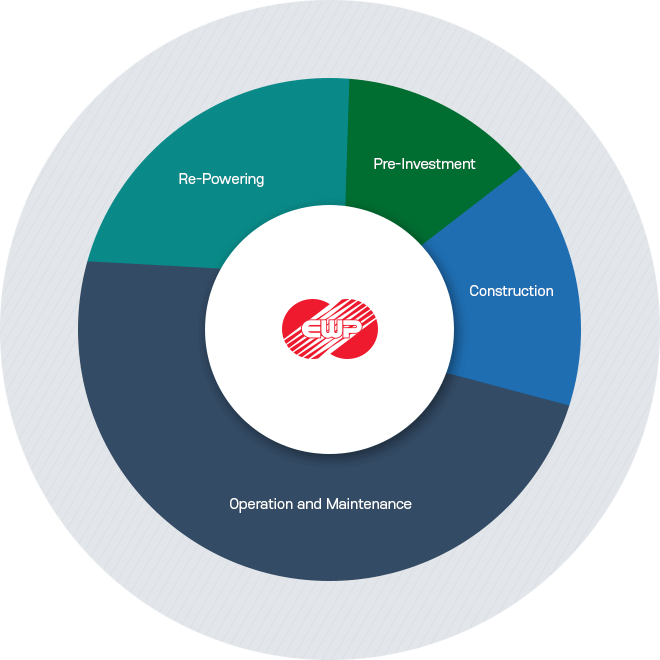

We provide independent technical advice and services across the entire lifecycle of power plant projects from pre-F/S, EPCM, and O&M to repowering with our expertise in technical consulting.

-

Project development solutions

Feasibility Studies

Proposal Evaluation

Consultancy services for investing in power plant projects

Conceptual design/front-end engineering

-

Project implementation solutions

EPCM / CM

Consulting to Lenders and Owners

Commissioning & Hand-over services

Quality Control and Assurance

-

Fuel management solutions

Fuel quality consultancy service

Evaluation of combustion practices

Installing fuel and combustion management IT systems

Consultancy in fuel procurement, fuel blends and fuel quality management

-

Operation solutions

Operator training

Remote Monitoring Services (RMS)

Operation data analysis, plant condition monitoring, and predictive maintenance recommendations

Consultancy service for the implementation of Plant Information System (PIS)

On-site balancing and vibration analysis services

-

Maintenance solutions

Failure investigations and root cause analysis

O&M mobilization and procedures

Maintenance optimization strategies and effective repair strategy recommendations

Consultancy services for implementation Plant Management System (PMS)

Facility Diagnosis

Maintenance Engineer Training

-

Re-powering design

Component condition evaluation and life assessment

Feasibility studies for projects involving retrofitting

Asset lifecycle cost optimization strategizing

We provide services based on our proven practices and tools including IT S/Ws and standardized job processes throughout the entire lifecycle;

for conventional steam power plants including CFBC, CCGT and biomass.

- Pre-Investment

Feasibility studies

Evaluation of proposals

Consultancy for investing power plant project

- Construction

EPCM / CM

LE / OE

QA / QC

Commissioning & hand-over

- Operation and Maintenance

Fuel management service

Plant condition remote monitoring

Data analysis and production support

Installing optimal IT systems

Combustion optimization

Plant performance and optimization testing

Vibration analysis, Predictive alarm

Personnel training

Maintenance optimization & outage maintenance strategy

Component life assessment

Asset lifecycle cost optimization strategy

Technical root cause / failure analysis

- Re-Powering

Life extension

Plant preservation

Retrofits F/S & Evaluation

Project Development

This phase is the most significant, because most of a project’s profitability and feasibility is fixed here.

Our specialty is carrying out tasks from an end-user perspective and our service spans everything from conventional power plants to renewables,

with a specialty in biomass power plants.

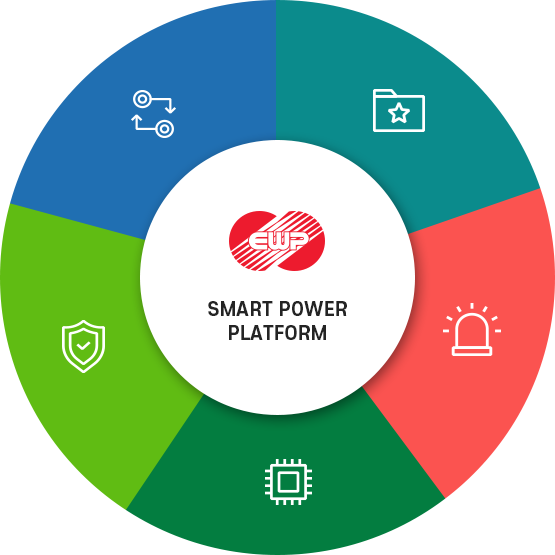

Our Solutions

(Pre-)Feasibility studies and evaluation of proposals

Evaluation of the technical, economic, environmental and social viability of a proposed project, including a comparison of alternatives

Recommendation of a preliminary design of the chosen solutions

Conceptual design front ? end engineering

Recommendation or implementation with our own experience and historical record ranging from USC coal fired plant to wood type biomass, as a end-user

Consultancy services for investing power plant project

Recommendation for achieving profitability of project by evaluating risk and opportunity in our business territory

Due diligence for merge and acquisition of domestic power plant asset

Your Benefits

Reducing both operational and construction costs by incorporating our knowledge and expertise obtained through operating and maintaining several types of plant

Our diversified plant operation experience will directly translate into your economic gain

- Bituminous coal-fired(USC) type

- Oil-fired and C. C. power complex

- Heavy oil-fired type and LNG combined cycle

- Anthracite coal-fired (CFBC) type

- LNG combined cycle

References

F/S and evaluation for Dangjin coal-fired plant fleet and Ulsan CC

- Dangjin 500MW USC-class coal-fired power plants #5, 8

- Dangjin 1,000MW SUSC-class coal-fired power plants #9, 10

- Ulsan combined-cycle

- Vietnam, 1,200MW coal-fired plant F/S

Donghae 30MW wood-type biomass power plant

- Planned out using our expertise gained from technical due diligence and risk management for both conceptual and basic design

- Still accumulating technical knowledge through our own O&M fleet

Project Implementation

We have collected cumulative project execution experience and best practices for the effective

implementation of EPCM projects through project supervision, project management, engineering management, procurement,

QA/QC commissioning, and other such project support tasks.

Our Solutions

EPCM / CM with 4D modeling S/W

We minimize conflicts among functional activities by using project management S/W enhanced by the 4 Dimensional solution

We support optimal project management and transferring documentation to operational phases

Consulting with lenders or owners

Preparation of ITB for EPC and evaluation for award

We inspect the quality of documentation from suppliers and EPC contractors

Basic Engineering

Quality assurance and quality control

Shop inspections and expediting

Commissioning and hand-over services

Our experienced experts will detect problems that could become serious issues during post-COD and suggest solutions

We prepare documents for future operators to preventing critical operational failures during the operation phase and training

Training for future operators in advance to prevent critical operational failures during the operation phase.

Your Benefits

Economic coal buying and coal quality control from our extensive knowledge and experience in coal procurement; we consume approximately 2 million of bituminous coal each year.

Understanding the effect of combining vessels with simulations enabled by our fuel management system and minimizing the cost of demurrage

Independent advice for fuel procurement and troubleshooting following fuel-related plant issues

Use of our tool to identify unknown coals and coal blends

Advice when you are involved in claims regarding a fuel quality issue.

References

We have developed 10 major power plant projects since 2000, including eight 500 MW USC coal- fired projects, one M501J class LNG CC project and one wood-type biomass plant.

We held a record for shortening the construction period for Dangjin #5?8 power plant, a cutting-edge 500 MW USC-class coal-fired power plant, which took 3.5 years with construction costs of 900 $/kW (where $1 = \1,200)

We have carried out owner’s engineering for following projects:

- Chuncheon district energy project (463MW, LNG, CC)

- Seokmun district energy project (40MW, Bio-SRF)

- Biomass mixing facility and coal store building at the Donghae site

Fuel Management

Fuel costs contribute almost 90% of the overall OPEX of coal-fired power plants and are highly dependent on the fuel quality.

Therefore, closely monitoring the fuel quality is critical for minimizing the generation costs, which is our specialty.

Our Solutions

Consultancy services for coal procurement

Recommendations for coal procurement strategies with in-house experts and information systems

Advice for coal specification with consideration of boiler-types restrictions

Advice for the procurement of documentation and processes

Advice for the method of hedging the volatility of fuel commodities without involving the commodities market.

Consultancy services for optimal fuel blends

New analytical methods for evaluating combustion behavior, particularly with regard to fuel blends

Fuel evaluation tool to assess the impact of fuel quality and price on plant economics, efficiency, emissions, by-products etc.

Advice for when trouble happens during fuel blending with the help of a combustion monitoring system, if you purchase from us or have records of it.

Fuel quality consultancy service

Guided by our standards and process policies to maintain the quality to that of the specification

Independent quality and process audits of manufacturers and suppliers

Advice for effective and efficient stock management practices

Installing customized fuel and combustion management S/W

Advice to install fuel and combustion management S/W

Optionally, purchase our proven S/W with EWP expert consultancy

Without a combustion monitoring system we can still give advice using our considerable historical combustion data and the troubleshooting record

Your Benefits

Project management optimization from a sponsor prospect, particularly using 4D tools to coordinate the construction process.

Using our construction records in the 4D modeling system of a 1000 MW coal-fired plant, Dangjin #9, 10

Ensuring that you keep your construction budget under the schedule and reduce the construction period by avoiding collisions between tasks

Minimizing trial and error in commissioning test operations, to enable the securing of optimal performance

EWP's abundant experience and outstanding construction allow us to design and construct various types of power plant employing our own engineering technologies.

References

We have developed 10 major power plant projects since 2000, including eight 500 MW USC coal- fired projects, one M501J class LNG CC project and one wood-type biomass plant.

We held a record for shortening the construction period for Dangjin #5?8 power plant, a cutting-edge 500 MW USC-class coal-fired power plant, which took 3.5 years with construction costs of 900 $/kW (where $1 = \1,200)

We have carried out owner’s engineering for following projects:

- Chuncheon district energy project (463MW, LNG, CC)

- Seokmun district energy project (40MW, Bio-SRF)

- Biomass mixing facility and coal store building at the Donghae site

Plant Operation

Our own data processing technology and affluent experience allows us to turn the large amount data produced by power plants into valuable information

that yields predictive alarms and actions, optimizing maintenance spending. Remote assistance via IT technology is also popular.

Our Solutions

Remote Monitoring Services (RMS)

Real-time monitoring of operation status at the EWP RMS center which can prevent critical facility failures

Accurate interpretation of the data from online vibration monitoring systems, which are equipped for most large turbine generators and critical plants, as a part of EWP RMS.

Periodic health monitoring reports

Consultancy services for the implementation of Plant Information System

Optimal S/W choice recommendations within customers’ budgets

Advice to configure optimal master DB and O&M processes

Consultancy services to utilize the IT S/W and extract real value of the system

Operation data analysis, PCM, and PM recommendations (Plant Condition Monitoring and Predictive Maintenance)

EWP Technologies provides effective and efficient data screening solutions, enabling you to extract value from the thousands of data signals that you have already collected.

We optimize your plant maintenance using the early detection of developing issues through statistical solutions proven by EWP expertise to monitor abnormalities and generate predictive alarms.

Our accredited vibration analysts recommend the optimal solutions using our own database of influence coefficients.

On-Off site training

Training your personnel in the O&M fleet with our learned experts both on- and off-site

Achieve real-time training effects by subscribing to EWP RMS

Your Benefits

Turn your plant data into useful information and knowledge to enable you to execute the best strategies for your assets

Reduce unplanned unavailability by providing the early detection of developing plant problems, thus enabling optimal planning solutions

Use EWP’s own knowledge and DB to install systems such as Plant Information System (PIS) and Plant management (PM) which are proven standard samples in South Korea and are followed by other major Gencos.

System installation with a lower budget and shorter time, and without colliding with other systems

References

Our integrated PMS and PIS system has proven its effectiveness by being followed by four other Korean Gencos.

Our experience of RMS carried out by global OEM

- Dangjin #4 : GE shield (prevented 217 outage events during 2015.02~2017.02)

- Ulsan #4CC : MHPS (reduced repair times by approximately 30%, 2013.11~2016.07)

Plant Maintenance

Besides monitoring and predictive maintenance it is significant to increase availability via optimal and

timely maintenance with asset lifetime maintenance strategies and determining the root cause to prevent repeating failures in the future.

Our Solutions

Maintenance Support

The remaining life managements has been applied after damage was found in a component as a method of determining whether to continue running a unit or replacing/repairing the component and thus preventing failures.

The accurate diagnosis and correction of vibration is needed to prevent machine failure in an early stage.

Maintenance optimization

Review and make recommendations regarding the O&M strategy, practice, budget plan including a spare parts strategy based on EWP’s best practices.

Optimize the lifetime performance and value of your assets using our OEM independent asset

Recommendations for cost effective repair strategies or replacement and/or re-engineering when necessary with a transparent approach to recommendations and decisions, often less conservative than OEMs

Failure investigations and root cause analysis

Our expert engineers can use their operation and design knowledge to rapidly analyze failures’ root causes.

Design reviews and operational assessments

Interaction with other technical experts from across our business in South Korea.

Pragmatic approaches to failure resolution that minimize operational losses

Independent performance assessments

Independent performance assessments conducted in accordance with internationally recognized test standards that cost significantly less than OEM’s.

Your Benefits

Minimization of repair periods and costs by optimizing maintenance periods and scope, and Increasing the availability , adding value through preventing repeat failures with the help of EWP technology experts and data-driven maintenance.

Value from optimum maintenance approaches for each item, time-based, condition-based, or hybrids thereof.

Safeguarding customers’ technical and commercial interests regarding warranties, claims and liquidated damages from OEMs.

Advice when anticipating performance shortfalls.

References

Awarded First Prize for "Longest Faultless Operation" in 2007~2009 and the "Best Performer" in 2010 by EUCG

EWP has organized the “EWP Technology Division’ for a decade, which comprises a bundle of technical experts in major equipment fields such as boiler and turbine.

First to achieve asset management standard ISO 55001 South Korea Gencos.

The average availability of the Dangjin coal power plant fleet is approximately 93.5%.

We carry out maintenance and equipment inspection on a Reliability Centered · Maintenance(RCM) basis with the help of PMS and PIS.

Re-powering Design

Considering the cost of assets throughout their lifecycle is crucial for the success of power plant

projects because spending less could lead to poorer future equipment performance.

The need to replace or rehabilitate aging infrastructure is increasing, which is where our experience of operating older power plants shines.

Our Solutions

Component condition evaluation and life assessment

Inspection and replacement strategies for boiler tubes and review of tube leak histories and trends

Investigation and prevention of corrosion-related failures.

Residual life assessment of main equipment such as boiler tubes.

Asset lifecycle cost optimization strategies

Asset lifecycle cost optimization strategies from new construction through to decommissioning, including life extension strategies

Plant status review/due diligence to determine asset condition, maintenance history, residual life, risks and investment requirements.

Feasibility study for retrofit project

F/S or owner’s engineering services for retrofitting projects ranging from of a conventional power plant to fuel conversion and re-powering to enhance performance

Life extension and plant preservation recommendations

Your Benefits

Advice for life expansion and plant preservation based on our experienced asset operator, fleet of special technical experts, and own project records.

Advice from the owner’s engineers and independent original equipment manufacturers from an end-user prospective.

References

Our fleet of experts in EWP technology group and facility inspections

- 32 mechanical equipment and 20 electrical equipment units

Lifespan expansion on coal power plants (250 MW × 2) at Honam site.

Plant preservation of the Ulsan oil power plants #1-3 (200 MW × 3) after reaching the supposed lifespan limit

Industry 4.0

Definition

Terms refer to not specific technology but the transition of the whole manufacturing industry

Next-Generation Industrial Revolution which increases manufacturing competitiveness by combining manufacturing & information and communication technology(ICT)

Industrial change which can be expected to a build of virtural physical system the real and the virtual are intergrated so that things could be controlled automatically and intelligently through robot & AI

Machine and machine communicate, cooperate and evolve with each other in a space where the reality and virtual are merged

Technology

Physics Technology : 3D printing, Dron, Automotous driving, Robotics, New materials

Digital Technology : ICBM(IoT, Cloud computing, Big data, Mobile)

![Degree of Complexity [From Industry1.0 Industry4.0] - Industry1.0: Mechanization of the factory by stream engine, Industry2.0: The start of mass production by power utilization, Industry3.0: Combination IT with electronic products Manufacture automation, Industry4.0: Cyber Physical System(CPS) based on intelligent production system](/eng/images/sub/industry4.jpg)

EWP Industry 4.0

Goal and Direction

Realization of the Most Intelligent Power Plant Operation Sys & Creation for New Growth Engine

Utilize the most advanced ICT Tech such as machine learning & Develop the world's most intelligent power operation system

- Effective and pleasant working environment where not only anyone could be easily monitoring and controlling but both manager and worker are comfortable

With the efficiency of power plant management, the system is being platformed and develops as a future growth engine that exports to the world market

EWP 4.0 system concept

Convergence Field Experience and Digital Information & Automatic Optimization of Power Plant Operation

Combine operating information collected in real time using thousands of sensors with field knowledge, experience and problem solving skills on power company(EWP)

Optimize automatically the whole power plant operation process from power plant design, construction to fuel procurement, combustion, surveillance, diagnosis, forecast and maintenance

Promotion strategy

Openness, Communication, Cooperation, Industrial convergence, Power Plant Industry 4.0 Alliance

Establish a strategic alliance for a combination of knowldege, experience and competence of Korea's top companies & Construct power plant industry 4.0 alliance

- Equipment Manufacturing, Power Plant Construction, Operation, Maintenance, ICT, Mobile Solution etc

Orient open type platform that is self-evolving with open innovation & Maximize creating and sharing value

Install and promote core T/F(Power technology development institute) jointly for propelling power plant industry 4.0

Sensor, IoT

Data storage / process

Monitoring based on

statisticsEarly warning system

Intelligent automative decision

Artificial Intelligence(AI)

Diagnostic tools, Algorithm

Risk based inspection sys

Data flow optimization

Asset, performance system